Investors who want to be in the business of recycling waste oil into diesel pay close attention to the cost of waste oil to diesel plant. In general, the cost of a waste oil to diesel plant is mainly affected by several factors: daily processing capacity, equipment configuration, and manufacturing materials and design. Only these aspects can be determined, basically the cost is also determined. Read the following carefully and it will help you to choose a good and affordable waste oil to diesel plant.

Waste oil to diesel plant project site

Waste oil to diesel plant project site

Daily processing capacity

The common used capacity of waste oil to diesel plant on the market is 5TPD, 10TPD, 15TPD and 20TPD. Of course, different processing capacity waste oil to diesel plant, different sizes, daily processing of raw materials quality is different, so the cost is also different. The cost may be proportional to the volume of daily processing capacity. For example, the cost of a 10TPD waste oil to diesel plant is almost twice that of a 5TPD waste oil to diesel plant.

Different processing capacity waste oil to diesel plant (also called used engine oil refinery plant)

Different processing capacity waste oil to diesel plant (also called used engine oil refinery plant)

Equipment configuration

In order to meet the needs of different customers, our waste oil to diesel plant design is available in optional configurations. If you have low requirements for oil products, you can choose standard configuration. If you have high requirements for oil products, you can choose deep purification system to get higher quality oil. So if the customer needs the different configuration, the cost of the waste oil to diesel plant will be different.

Deep purification system

Deep purification system

Manufacturing materials

As a large machine, the manufacturing materials are very important. So DOING company in the production of materials strictly control, and all the use of high standard steel plate and pipe. Compared to machine made of ordinary materials, the cost of DOING waste oil to diesel plant is higher.

High standard steel plate and pipe

High standard steel plate and pipe

Design

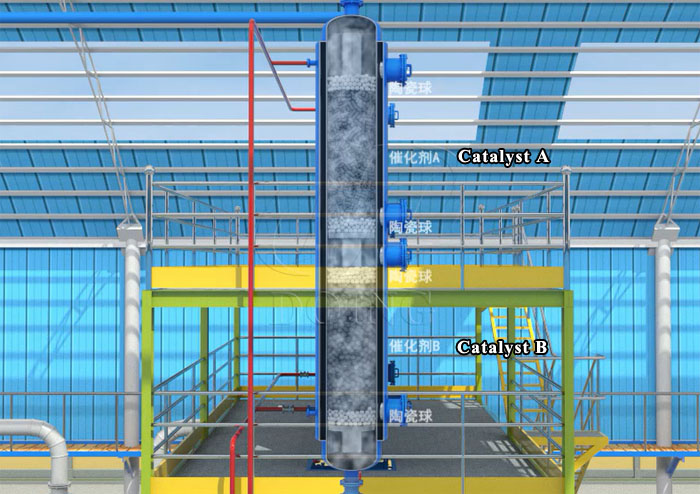

Even if the above items are the same, the cost of the waste oil to diesel plant varies depending on the design and construction of the plant. The design and construction of the equipment depends largely on the treatment process. For example, DOING has two designs for waste oil to diesel plant. One is an older process that mainly uses acids and bases, and the other is a newer design that uses solid catalysts. Newly designed waste oil to diesel plant have higher oil yield and shorter reaction times, so the price will be higher.

Newly designed waste oil to diesel plant with solid catalysts

Newly designed waste oil to diesel plant with solid catalysts

To sum up, the cost of waste oil to diesel plant mainly depends on these aspects. But these are not enough when buying waste oil to diesel plant. Choose the manufacturer rather than the trader. Because the manufacturer can give you technical support, but also provide perfect after-sales service.

We DOING Company, since 2011, which has been specialized in waste recycling machinery for more than 10 years. Our main supply scope includes solid waste (waste tire, rubber, plastic, etc) recycling to fuel oil machine and waste oil (waste oil, used motor oil, crude tire/plastic oil, etc) recycling to diesel machine, etc. If you are interested in this project, please contact us directly!