All customers who start a pyrolysis plant project must consider the issue of revenue. Knowing the profits of the project will strengthen the determination to do the project. Next, we will analyze the profit of the fully automatic pyrolysis plant.

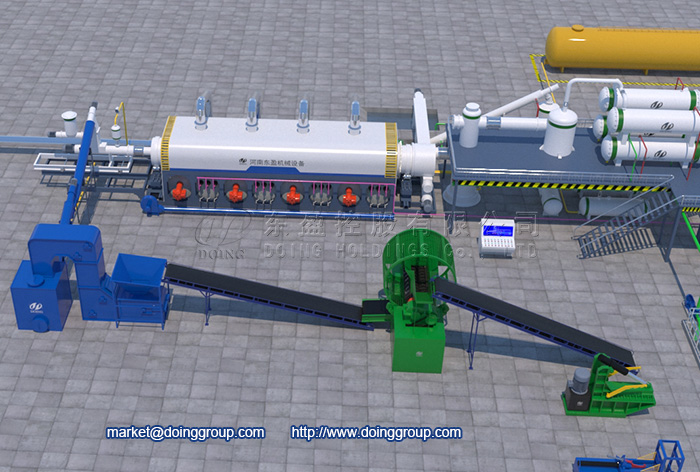

DOING fully automatic pyrolysis plant

DOING fully automatic pyrolysis plant

Compared with batch type pyrolysis plant, fully automatic pyrolysis plant has higher cost and larger processing capacity. Therefore, we will recommend customers who has large quantity of material with this fully automatic pyrolysis plant, the smallest process capacity should be 30t per day.

So we will take 30 tons fully automatic tyre pyrolysis plant as an example to analyze the profits. We'll figure out the operation cost and the income separately, and then the income minus the cost is the profit.

Operation cost

Generally speaking, operating costs mainly include fuel cost, power cost and labor cost.

1. Fuel cost

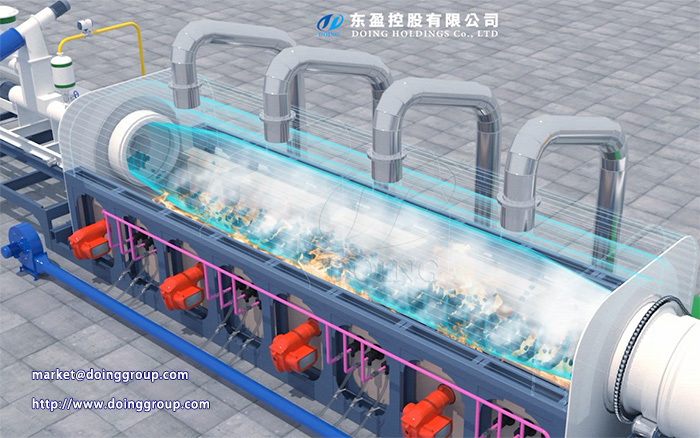

When the fully automatic tyre pyrolysis plant is preheated, it will consume 600 kg of fuel oil. After that, the fully automatic pyrolysis plant will use self-produced tail gas as fuel, and no other fuel is needed. You can work out the cost of fuel in terms of the market price.

Preheat the fully automatic pyrolysis plant

Preheat the fully automatic pyrolysis plant

2. Power cost

The average power of the fully automatic pyrolysis plant is about 60 kW per hour and the power consumption for 24 hours is 1440 kW.

3. Labor cost

The fully automatic pyrolysis plant needs 3 workers to operate, so you need to pay them according to local standards. Plus these three numbers you can calculate your daily operating cost based on local prices.

Income

The 30 tons fully automatic tyre pyrolysis plant can produce 13.5 tons of heavy oil, 9 tons of carbon black, and 4.5 tons of steel wire per day. These products are widely used in life, so they have a good market price.

Final products and their applications of fully automatic tyre pyrolysis plant

Final products and their applications of fully automatic tyre pyrolysis plant

Similarly, you can also calculates your daily income according to your local price of these final products, after subtracting the operation cost, you will get your daily profit.

Profit

| Profit analysis(Reference to process 30 ton fully automatic tyre pyrolysis plant) | |

| Operation cost / Day/30T | |

| Waste tires | 2194USD /30T |

| Heating fuel (Just choose one from the options) | 1)Coal: 105USD 2)Fuel oil: 562USD 3)Diesel:632USD 4)Natural gas: 148USD |

| Power consumption | 75Kw/h/30T |

| Water consumption | Water is for circulating use, no consumption |

| Required workers | 3 workers per shift /197USD/Day |

| Income / Day | |

| Fuel oil | 13.5T:4936USD |

| Carbon black | 9T:1)selling directly, 658USD 2)grinding, 2633USD |

| Steel wire | 4.5T: 527USD |

| Daily profit (Use fuel oil for heating and sell carbon black directly) | 3927USD/Day |

In general, our fully automatic pyrolysis plant is more suitable for customers with large investment scale, large amount of raw material processing, and high local labor costs, and fully automatic pyrolysis plant is a future trend.

If your country’s government supports the waste plastic or tire pyrolysis project , you can try to apply for a certain subsidy fee, which will greatly reduce your investment cost and earn more profit. If you want to know more details about the fully automatic pyrolysis plant, please contact us directly.