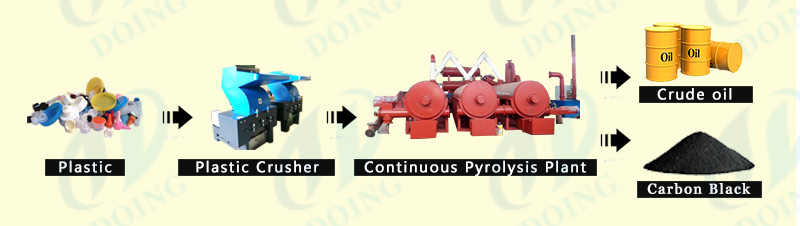

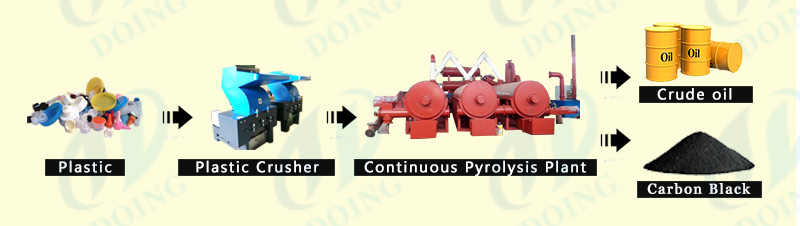

Continuous waste plastic pyrolysis plant

Our Doing continuous waste plastic pyrolysis plant can continuously process plastic into crude oil and carbon blacks without stop. All the continuous waste plastic pyrolysis plant is controlled by PLC(programmable logic controller), so it is very easy to operate it and our customers can save much cost of time and labor.

The raw material of continuous waste plastic pyrolysis plant is waste tire ,waste plastic ,waste rubber

Then how does a continuous waste plastic pyrolysis plant work? The best answers as follow:

Work process of continuous waste plastic pyrolysis plant

1.All available plastic can be shredded by plastics crusher, and then feed plastic granules directly into continuous waste plastic pyrolysis plant through the feeding door.

2.Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor No 1, then all the plastic can be decomposed under the high temperature through reactor No 1 to reactor No 2,then to reactor No 3...Until all the plastic fully pyrolysed, then all the carbon black powder will be discharged automatically to the carbon black tank.

3. All the available oil gas will be cooled by circulation water and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant,the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and water resource,in this way, our continuous waste plastic pyrolysis plant can minimize your cost and maximize your profits.