The cost of one set waste plastic pyrolysis plant mostly has a range. The specific cost also needs to be confirmed with the engineers of the waste plastic pyrolysis plant manufacturer. The cost of waste plastic pyrolysis plant is related to the thickness, material and process technology of the selected steel.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

When purchasing waste plastic pyrolysis plant, it is necessary to shop around for cost-effective, high-quality waste plastic pyrolysis plant. So what should be considered seriously is not only the cost of the waste plastic pyrolysis plant. DOING also suggests that you consider the following questions:

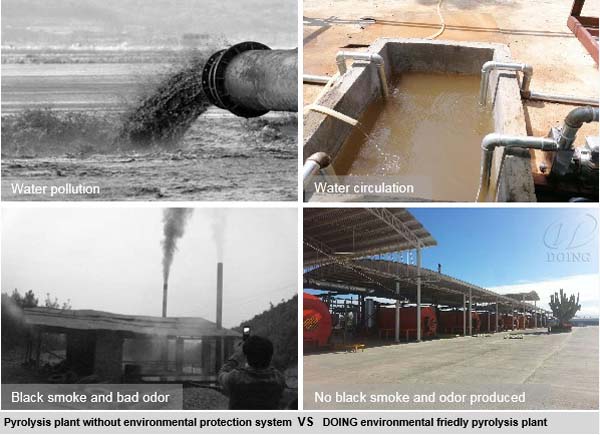

1. Environmental protection of waste plastic pyrolysis plant

The environmental protection aspect of waste plastic pyrolysis plant is still relatively important. At present, many waste plastic pyrolysis plants are cheap, but lack the corresponding environmental protection configuration, which leads to odor, black smoke and dirty during the operation. DOING Company recommends the waste plastic pyrolysis plant with environmental protection devices. In this way, no matter whether it is in or after the equipment operation, it has no black smoke and no odor produced, thus achieving environmental protection requirements. The waste plastic pyrolysis plant produced by Henan DOING is equipped with a dust removal and deodorization device, and the discharge of waste water and waste gas in the running process can meets the standards.

Different environmental protection configuration

Different environmental protection configuration

2. The oil yield of waste plastic pyrolysis plant

The oil yield of waste plastic pyrolysis plant is related to the technical process and design from different suppliers. The main two factors that have the greatest influence on the oil yield of waste plastic pyrolysis plant are whether the plastic can be fully cracked and whether the oil and gas can be cooled adequately.

The pyrolysis reactor of DOING adopts a rotating design, which can uniformly heat and ensure the full cracking of waste plastics. At the same time, DOING cooling system are designed with three-stage condensers to ensure adequate cooling of oil and gas and high oil yield.

DOING cooling system

DOING cooling system

3. The service life of waste plastic pyrolysis plant

Generally speaking, the materials used in the waste plastic pyrolysis plant are different, and the service life will be different. Henan DOING waste plastic pyrolysis plant is made of high temperature resistant boiler steel plate material and is made of pressure vessel standard. It is resistant to high temperature and high pressure and is not easy to crack. Compared with other materials and designs, Henan Dongying waste plastic pyrolysis plant is more durable and has a longer life.

DOING pyrolysis reactor

DOING pyrolysis reactor

Regardless of the cost difference in the market, the first you must consider the above points when purchasing. It will help you to buy a good machine with a reasonable price. If you want to know more about the waste plastic pyrolysis plant, please contact DOING.