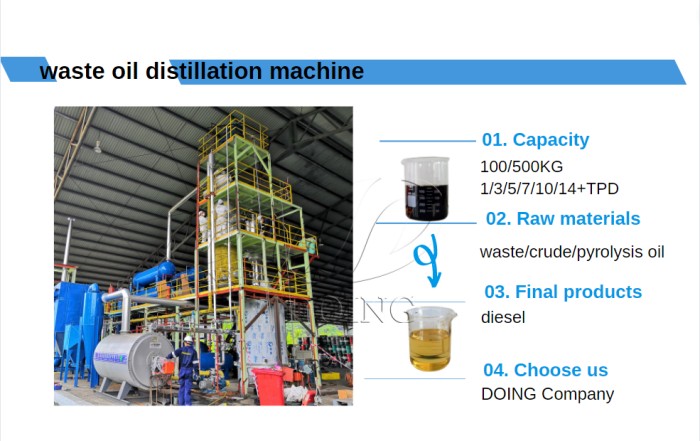

In the realm of waste oil recycling, a waste oil distillation machine plays a crucial role in transforming waste oil into valuable products. DOING waste oil distillation machine offers comprehensive and efficient approaches to meet your needs. The waste oil distillation machine from DOING Company is suitable for the disposal of a varity of waste oils, such as pyrolysis oil, waste engine oil and motor oil. It follows a well-established steps to convert waste oil into high-quality products like diesel and asphalt to achieve the efficient waste oil dispoal.

Waste oil distillation machine overview

Waste oil distillation machine overview

Preparation and Heating: Waste oil is first fed into the reactor. The reactor is heated to remove moisture and initiate the pyrolysis process. DOING waste oil distillation machine reactor is vertical, and there is a heat transfer oil coil in the vertical reactor ensures rapid and even heating, which is crucial for efficient processing.

Pyrolysis and Distillation: As the temperature rises, the oil undergoes pyrolysis, breaking down into smaller hydrocarbon molecules. The resulting vapors are then distilled, separating the components based on their boiling points.

Cooling and Condensation: The distilled vapors are cooled in a condenser, where they condense into liquid form. This liquid is collected in storage tanks for further processing.

Purification: This step is divided into two categories. Our traditional distillation machine uses liquid catalysts, which are acid and alkali solutions, to purify the oil. This helps remove contaminants, resulting in a higher quality end product. It works, but creates waste and requires additional handling and purchase of acid and alkali materials. Our new distillation machine uses solid catalysts, steam passes through a catalytic tower, and the solid catalyst is used to further distill the oil. This technology is more environmentally friendly and more efficient.

Different types of waste oil distillation machine

Different types of waste oil distillation machine

Outputs: The products of waste oil distillation include diesel, asphalt and exhaust gas. Each product can be used in different ways. Diesel can be used in boilers, generators, engines. Asphalt can be used for paving roads. Non-condensable exhaust gas can be recycled and used to heat distillation reactor. Each can produce different economic benefits.

Both models of DOING waste oil distillation machine offer substantial environmental benefits. Our machines feature advanced waste gas treatment systems, ensuring that emissions are minimized and meet environmental standards. They help in reducing waste oil pollution and contribute to a circular economy by converting waste into valuable resources. Economically, our waste oil distillation machine provides a cost-effective solution for waste oil management, generating revenue from the sale of refined oil products.

Waste oil distillation machine composition

Waste oil distillation machine composition

Whether you choose the traditional or new model, DOING waste oil distillation machine is designed to meet your specific needs. They provide a reliable and efficient solution for waste oil disposal and recycling. If you are interested in DOING waste oil distillation machine or would like to discuss how it can benefit your business, please feel free to contact us. We are here to help you make the best choice for your waste oil recycling needs.