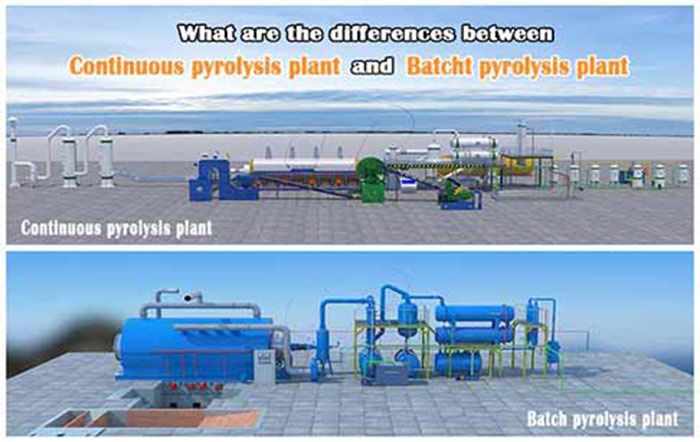

Many customers who buy waste tire pyrolysis plant often ask: What is difference between batch and continuous waste tire pyrolysis plant? This issue is also the concern of all those who are also interested in investing in waste tire refineries. Here I will make a summary and answer for everyone.

Batch and continuous waste tire pyrolysis plant

Batch and continuous waste tire pyrolysis plant

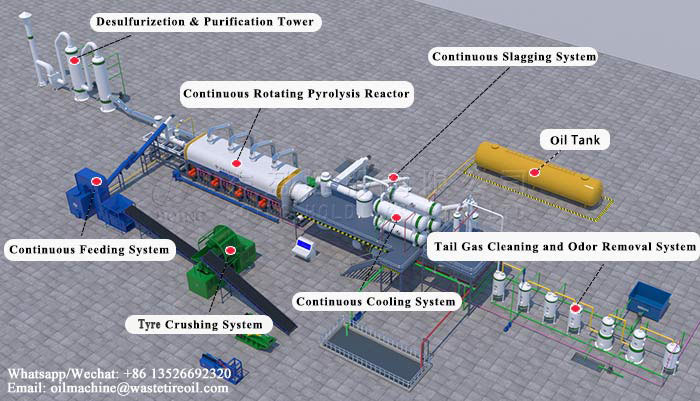

1.Different waste tire process routes

The continuous pyrolysis plant first needs to pre-treat the waste tires, tear the waste tires into small pieces and seal the materials in and out automatically. The batch pyrolysis plant does not pre-treat the tires, and uses open feed and discharge.

2.Different degrees of automation

The continuous pyrolysis plant adopts PLC control system , with less labor, 1-2 people in a single production line and low labor intensity. The batch pyrolysis plant is manual or semi-automatic, the single processing capacity is 3-4 people, and the labor intensity is high.

3.Different processing capacity

The processing capacity of batch pyrolysis plant is 100 kg, 500 kg, 1 ton, 2 tons, 5 tons, 10 tons, 12 tons and 15 tons, while continuous pyrolysis plant can handle 15 tons, 20 tons, 30 Tons and 50 tons. The continuous pyrolysis plantprocessing capacity is greater.

Continuous waste tire pyrolysis plant components

Continuous waste tire pyrolysis plant components

Both batch and continuous pyrolysis plant can achieve the purpose of getting oil. The continuous pyrolysis plant has a large single machine processing capacity and high efficiency, but the investment cost is also high. If you want to learn more about the plants, you can contact us at any time, our salesman will help you choose the most suitable plant.