Continuous tire pyrolysis plant

The Dongying Group's continuous waste tire cracking equipment adopts a PLC control system to continuously feed materials and continuously discharge materials. The pyrolysis principle is mainly used to crack waste tires into fuel, carbon black, steel wire, and combustible gas. So what types of equipment are there? What is the capacity of each model? This article will answer your questions!!!

Tchnical data of continuous tire pyrolysis plant production

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

The final products of DoingGroup's continuous pyrolysis plant have a wide usage in our daily life, specific usages are as follows:

Fuel oil usage

1.Fuel oil:Mainly used in Steel factory,boiler heating,heavy oil generator, cement factory.

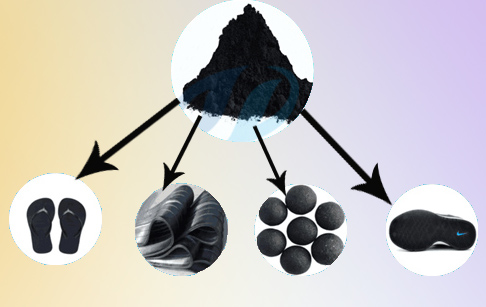

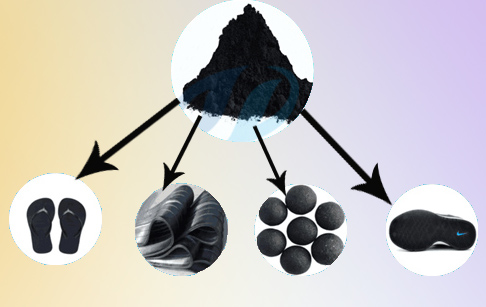

Carbon black

2.Carbon black:Mainly used in briquetting for burning or refining.In additon ,the refining also canbe used for new tire ,shoe soles ,paint.

Steel wire usage

3.Steel wire:Mainly be sold as scrap or remelting.