How does continuous pyrolysis plant works?

2020-12-30 / Continuous Pyrolysis plantContinuous pyrolysis plant is based on intermittent pyrolysis plant design and manufacturing, but the price is much higher than the intermittent pyrolysis plant. The main difference is in the structure and working process of the equipment. After understanding how does the continuous pyrolysis plant works, you will more identify with the continuous pyrolysis plant.

DOING continuous pyrolysis plant

DOING continuous pyrolysis plant

Next, we will focus on the continuous tire pyrolysis plant and continuous plastic pyrolysis plant how to work?

Cotinuous tire pyrolysis plant working process

Main working process of cotinuous tire pyrolysis plant

Main working process of cotinuous tire pyrolysis plant

♦ Waste tyre pretreatment

1. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tires.

2. Shred tires: Use a specialized tire shredder to process big whole tires into 3-5cm small pieces for easy feeding.

♦ Feeding waste tyres

The small pieces waste tyre will be hermetically fed into the reactor of the continuous pyrolysis plant through the transfer device.

♦ Heating and continuous pyrolysis process

Heating the pyrolysis reactor through the heating furnace. DOING continuous pyrolysis plant adopts indirect heating system, so the flame does not directly contact the inner wall of reactor. During the heating process, the reactor can be rotated 360 degrees, so that the waste tires inside are evenly heated. When reach a certain temperature, waste tires will generate oil gas.

♦ Cooling and discharging

The oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous dischrge system for discharge.

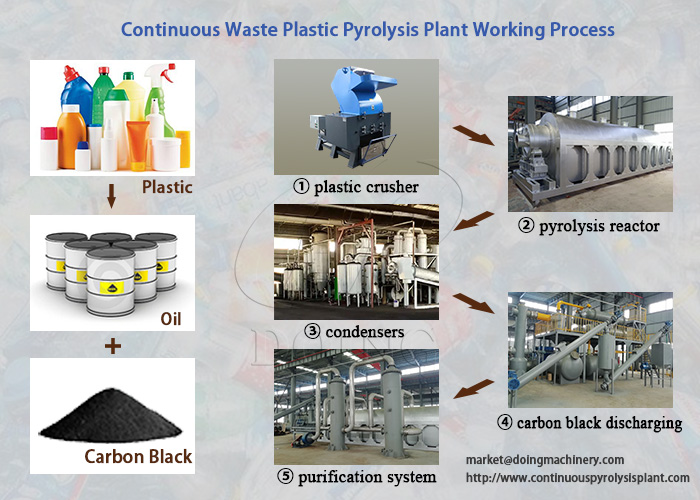

Continuous waste plastic pyrolysis plant working process

Main working process of cotinuous waste plastic pyrolysis plant

Main working process of cotinuous waste plastic pyrolysis plant

♦ Waste plastic pretreatment and feeding

All available plastic can be shredded by plastics crusher, and then feed plastic granules directly into plastic continuous pyrolysis plant through the feeding door. Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor.

♦ Heating and continuous pyrolysis process

General plastics will contain water. When the beginning of heating, the water in the plastic will be the first to evaporate. After water completely eliminated, with the rise in temperature, waste plastics will be pyrolyzed to produce oil gas. Compared to the treatment of waste tires, plastic heating time and pyrolysis time is shorter.

♦ Cooling and un-condensable gas recycling

All the available oil gas will be cooled by circulation water and the un-condensable gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant, the circulation water cooling system and un-condensable gas recycling system will help you save much fuel and water resource, in this way, DOING continuous waste plastic pyrolysis plant can minimize your cost and maximize your profits.

The above is the main working process of the tire and plastic continuous pyrolysis plant. But different raw materials, slightly different treatment aspects. But the equipment efficiency, high oil yield and environmental protection are the same. If you have plans for investment projects, please contact us directly.