Tips for regulating emissions in pyrolysis plants

2026-01-06 / Industry NewsThe treatment and emission of pyrolysis gases are crucial factors in evaluating the environmental performance of pyrolysis plant. DOING, a supplier with over a decade of experience in pyrolysis equipment manufacturing, considers these factors and local policy requirements when configuring pyrolysis units, implementing a comprehensive range of emission control measures. These pyrolysis plant emission control and regulation mainly covers the following 4 tips:

1. Raw Material Pretreatment

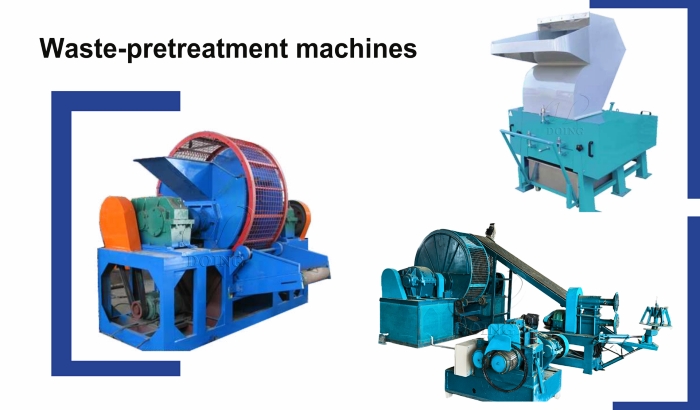

Proper preparation of raw materials is a foundational step in controlling emissions from pyrolysis plants. By addressing contaminants before the pyrolysis process begins, you can minimize the release of harmful substances during heating.

Start by sorting and cleaning the feedstock to remove non-combustible materials, metals, and high-chlorine components like PVC plastics. Using mechanical separators or shredders to break down waste and eliminate impurities. This reduces the formation of dioxins and heavy metals in the pyrolysis flue gas. Additionally, drying the materials to lower moisture content prevents excessive steam generation, which can carry pollutants into the emissions.

Suppliers of pyrolysis plants, such as DOING Company, provide integrated pretreatment systems that can be incorporated into the pyrolysis plant design. This not only reduces downstream pollution but also improves the overall efficiency of the pyrolysis process, thereby lowering energy consumption and overall emissions.

Pyrolysis plant waste-pretreatment machines

2. Flue Gas Purification Systems

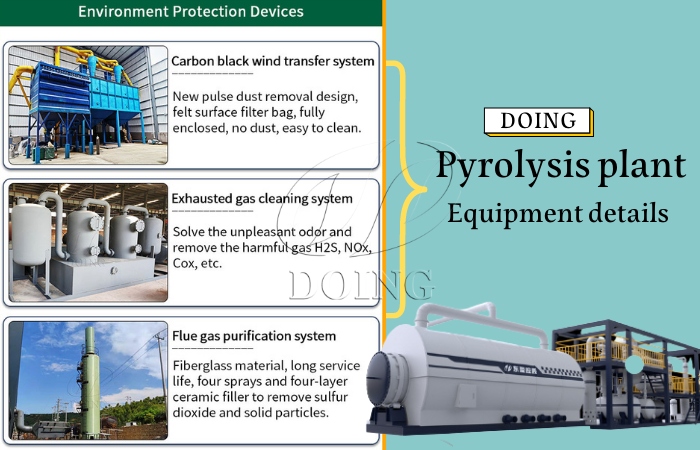

Once generated, flue gases from the pyrolysis reactor must undergo multi-stage treatment to capture pollutants before release. A well-configured purification system targets particulate matter, sulfur oxides (SOx), nitrogen oxides (NOx), and toxic organics. The following provides an overview of the environmental protection equipment configuration of DOING pyrolysis plant suppliers, including pulse dust collectors, spray towers, desulfurization and denitrification towers, combustion chambers, and activated carbon adsorption devices.

Pulse Dust Collector: This device uses compressed air pulses to clean filter bags, efficiently removing fine particulate matter and dust from the flue gas stream. It prevents dust accumulation and ensures cleaner emissions by capturing tiny particulate matter.

Pulse dust collector

Spray Tower (Waste Gas Purification Device): In this wet scrubbing system, water or chemical solutions are sprayed into the gas flow to cool it and absorb soluble gases like hydrogen sulfide. It serves as an initial treatment to reduce acidity and condense vapors, making subsequent steps more effective.

Pyrolysis plant waste gas purification device

Desulfurization and Denitrification Tower: This tower employs chemical reactions for SOx removal and selective catalytic reduction (SCR) to remove NOx, to neutralize sulfur and nitrogen compounds.

Pyrolysis plant desulfurization and denitrification tower

Combustion Chamber: The Combustion Chamber is designed to fully combust the non-condensable pyrolysis gases at high temperatures, converting them primarily into carbon dioxide and water vapor, while destroying many organic pollutants.

Pyrolysis plant exhaust gas combustion chamber

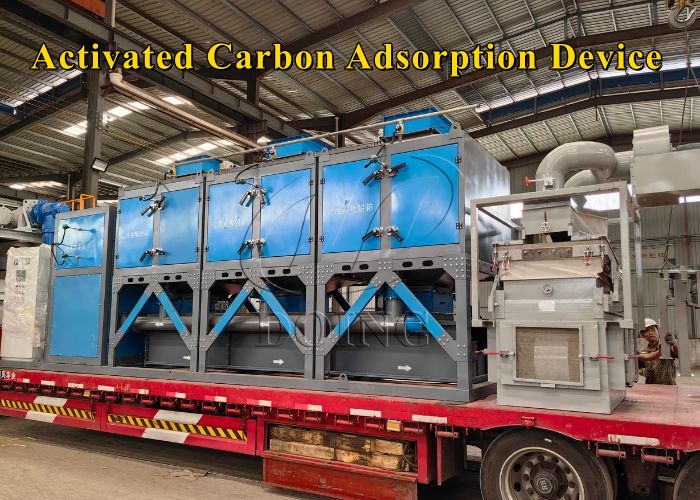

Activated Carbon Adsorption Device: The activated carbon adsorption device effectively adsorbs and treats residual organic pollutants, heavy metals, and odors during the process. The carbon can be regenerated or replaced periodically to maintain efficiency.

Activated carbon adsorption device

These components can be combined to form a multi-stage exhaust gas purification system that, according to industry standards, can achieve a reduction of over 95% in key pollutant emissions.

DOING pyrolysis plant environment protection devices

3. Optimizing Operation Management and Maintenance

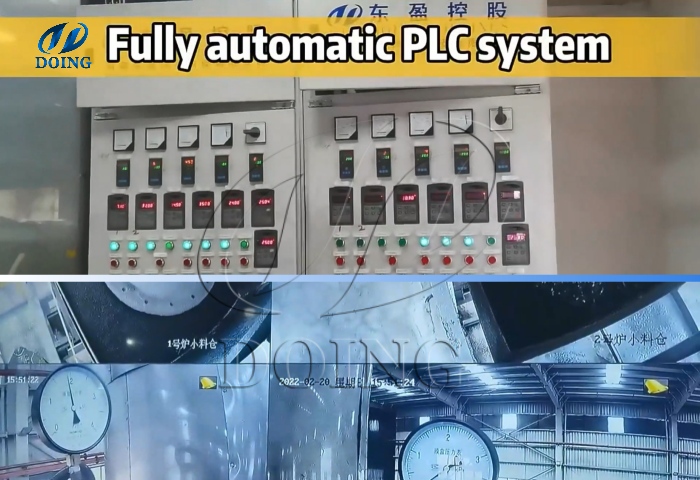

You can optimizing emission management through the tips of precise control and routine upkeep to maintain system performance.

The waste tire/plastic/oil sludge pyrolysis process should be carried out under anaerobic or micro-aerobic conditions. By reducing the temperature to below 600 degrees, harmful substances are decreased;

Implement a Programmable Logic Controller (PLC) system to automate monitoring and adjustment of critical parameters, such as reactor temperature, gas residence time, and airflow rates. This prevents overloads that could spike emissions and allows real-time tweaks based on feed variations.

Pyrolysis plant PLC system

Regular maintenance is equally important. Schedule weekly inspections of filters, valves, and scrubbers to check for wear or blockages, and perform quarterly deep cleans to avoid efficiency drops. Training operators on these protocols, including how to respond to alarms or shutdowns, further minimizes risks from human error.

4. Strengthening Monitoring, Supervision, and Compliance

Continuous oversight ensures that emission controls remain effective and adaptable to changing regulations. A robust monitoring framework detects issues early and supports data-driven improvements.

Customers can choose pyrolysis plants equipped with emission monitoring systems that provide real-time monitoring of carbon monoxide, sulfur oxides, nitrogen oxides, and particulate matter emissions. These systems are connected to a central control panel, which immediately triggers an alarm if emission levels exceed predefined thresholds.

In terms of compliance, DOING pyrolysis plants are certified with environmental management systems such as ISO and CE.

DOING pyrolysis plant quality certificates

Regulating emissions in pyrolysis plants different tips and approaches: from raw material pretreatment to advanced purification, disciplined operations, and vigilant monitoring. By applying these measures, the environmental impact of the pyrolysis process can be significantly reduced. For site-specific recommendations, please feel free to contact DOING. We have implemented pyrolysis projects in over 100 locations worldwide, and we can effectively develop solutions based on local emissions data.