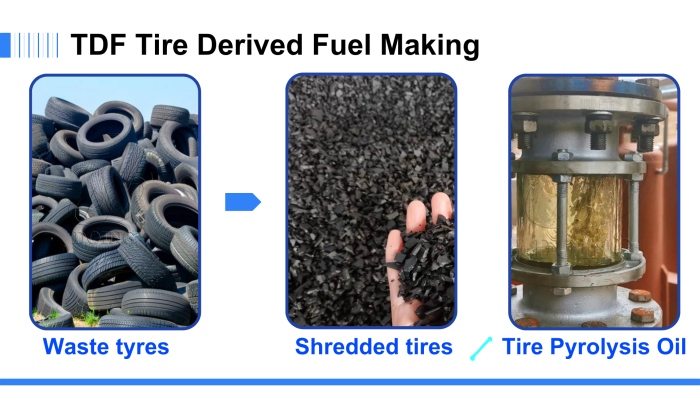

Mexican Client Chose DOING 15-Ton Batch Tire Pyrolysis Equipment

2025-10-16 / DOING NewsDOING is pleased to announce the successful signing of a contract with a Mexican client for a 15-ton batch tire pyrolysis equipement. The collaboration began in July 2025 and the partnership was officially established in September.

DOING tire pyrolysis equipment

We began contacting a Mexican client seeking to establish a tire pyrolysis business in July 2025. They were not only seeking tire pyrolysis equipment, but also a reliable partner with proven expertise. Our technical consultations in late July by showcasing our mature project cases in Mexico and Indonesia. The reference project in Mexico, in particular, reinforced their confidence in our equipment.

A client visited our facility in early September. Their initial concerns were operational safety and minimizing environmental impact. Therefore, during this visit, our project manager presented a detailed demonstration of our equipment's safety and environmental design, taking into account our current production situation and the equipment layout within our facility. These features encompass every aspect of our pyrolysis equipment, including:

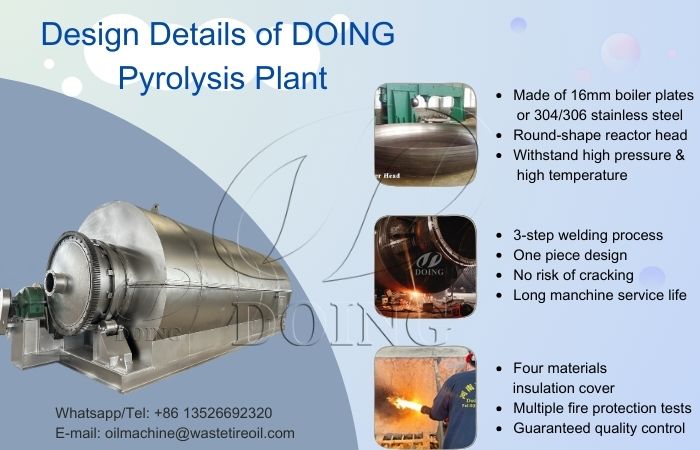

DOING Pyrolysis Equipment Safety Design

Selected Q245R/345R steel, utilizing a three-step, integrated, precision welding process, ensures high-temperature resistance, resists cracking and deformation, and offers a long service life. The equipment is equipped with supporting rollers, seals, and stainless steel guide rails to ensure the reactor's stability and concentricity under high-temperature and high-pressure conditions, ensuring more stable operation.

Design details of DOING batch tire pyrolysis equipment

Professional industrial condensers and buffer tanks ensure oil and gas cooling, while DOING's specialized vacuum system ensures high oil yield and prevents flash explosions when the reactor door is opened during equipment shutdown, enhancing safety.

DOING pyrolysis equipment condensors

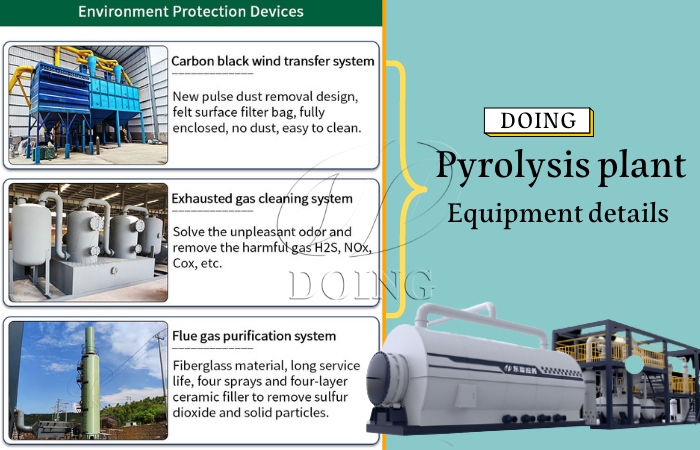

DOING Pyrolysis Equipment Environmental Protection Devices

Exhaust Gas Treatment System

This system captures and purifies pyrolysis exhaust gases using a multi-stage process: cyclone dust removal, filter, and catalytic combustion. It removes harmful substances and particulates. This ensures compliance with strict emission standards, reducing air pollution effectively.

Water Cooling and Recycling Unit

The unit employs closed-loop cooling towers and condensers to recycle process water, preventing wastewater discharge. It cools pyrolysis vapors efficiently. This design conserves water resources.

Odor Control Device

Equipped with activated carbon adsorption towers and filters, this device neutralizes odors from pyrolysis off-gases. Filters break down volatile organic compounds, while carbon adsorbs residual smells. It maintains a odor-free operation, protecting nearby communities and meeting local air quality regulations.

DOING batch tire pyrolysis equipment environment protection devices

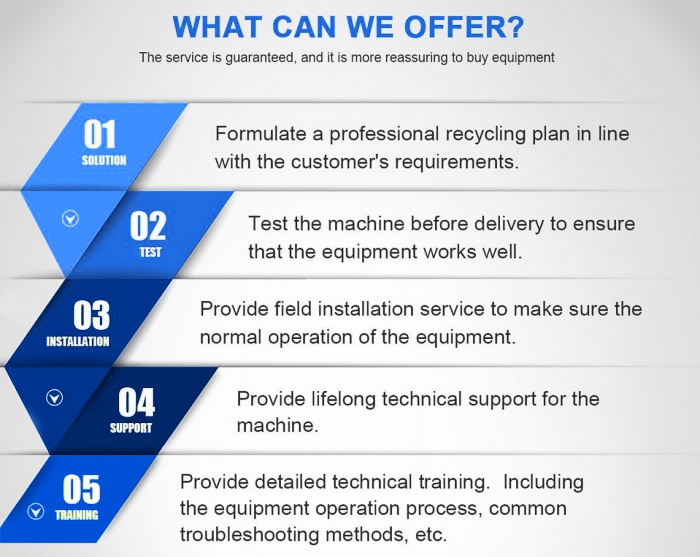

This granular examination allowed them to see firsthand the robust construction and professional engineering that underpin our pyrolysis plants. The client noted that our attention to these essential details demonstrated extensive experience and professionalism, distinguishing us from competitors. In September, the customer finalized a contract for a 15-ton batch tire pyrolysis equipment.

DOING batch tire pyrolysis equipment manufacturer

DOING has always been committed to providing customers with high-quality pyrolysis machine and high-quality services. We look forward to welcoming you and collaborating with more customers.