DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

2024-12-10 / In AmericaCongratulations! In December, 2024, DOING enginner helped our Brazilian customer successfully install three sets of semi-continuous pyrolysis plants, whose professional technical skills and responsible attitude won the praise and good feedback of the Brazilian customer.

Equipment overview

| Equipment | Pyrolysis plant |

| Capacity | 15TPD |

| Machine type | Semi-continuous |

| Processed material | Waste tires |

| Final products | Fuel oil, carbon black, syn-gas |

| Machine configurations | Pyrolysis reactor, buffer tank, oil-water seperator, cooling system, safety device, environmental protection systems, etc. |

Customer demands overview

DOING first received the inquiry of the Brazilian customer in February, 2024. After establishing contact with the Brazilian customer, the DOING sales manager made a detailed learning for the basic situation and demands of the customer. The Brazilian customer owned a set of pyrolysis plant before, whose work performance and efficiency can’t meet the demands of the Brazilian customer, so the most important factors he paid attention to are the equipment quality, work efficiency and the professionalism of the whole sales and engineering team of the machine manufacturer and supplier.

DOING semi-continuous pyrolysis plant for sale

DOING semi-continuous pyrolysis plant for sale

Project scheme overview

Based on the actual situation and demands of the Brazilian customer, DOING sales manager recommended the 15TPD semi-continuous pyrolysis plant. On the one hand, its processing capacity is suitable for the Brazilian customer; on the other hand, the semi-continuous design pyrolysis plant can discharge the carbon black in the high temperature, enhancing the work efficiency, meeting the demands of the customer. And to provide a more authentic learning for the machine quality of DOING pyrolysis plant, DOING invited the Brazilian customer to visit the DOING manufacturing factory. In the factory, the Brazilian customer visited the manufacturing process of the pyrolysis plant and the test running of DOING test machine in the factory, which won the recognition of the Brazilian customer. Finally, we reached the friendly cooperation with the Brazilian on three sets of 15 TPD semi-continuous pyrolysis plants in March, 2024.

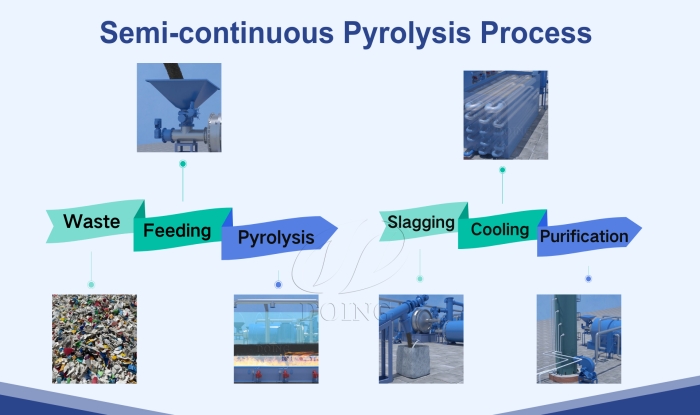

Work process of DOING semi-continuous pyrolysis plant

Work process of DOING semi-continuous pyrolysis plant

Equipment delivery and installation

After signing the contract with the Brazilian customer, DOING immediately sent the production notice to the factory. In the following several months, the three sets of semi-continuous pyrolysis plants were shipped to Brazil. After arriving in Brazil, DOING engineer made serious and patient technical guidance and training for the project installation. During the installation process, DOING engineer helped the Brazilian customer make detailed scheme planning and ensure the successful installation of the pyrolysis plant.

The following is the installation site of these three sets of semi-continuous pyrolysis plants in Brazil:

Installation site of semi-continuous pyrolysis plant in Brazil

Installation site of semi-continuous pyrolysis plant in Brazil

In addition to Brazil, DOING also has many successful pyrolysis plant projects in other countries of South America, such as Argentina, Peru, Chile, Colombia, Venezuela, Bolivia, Ecuador, etc. So if you also have a business plan for a pyrolysis plant, just feel free to contact us directly, we will provide comprehensive services for you!